A Story of Innovation in Surface Finishing Technologies

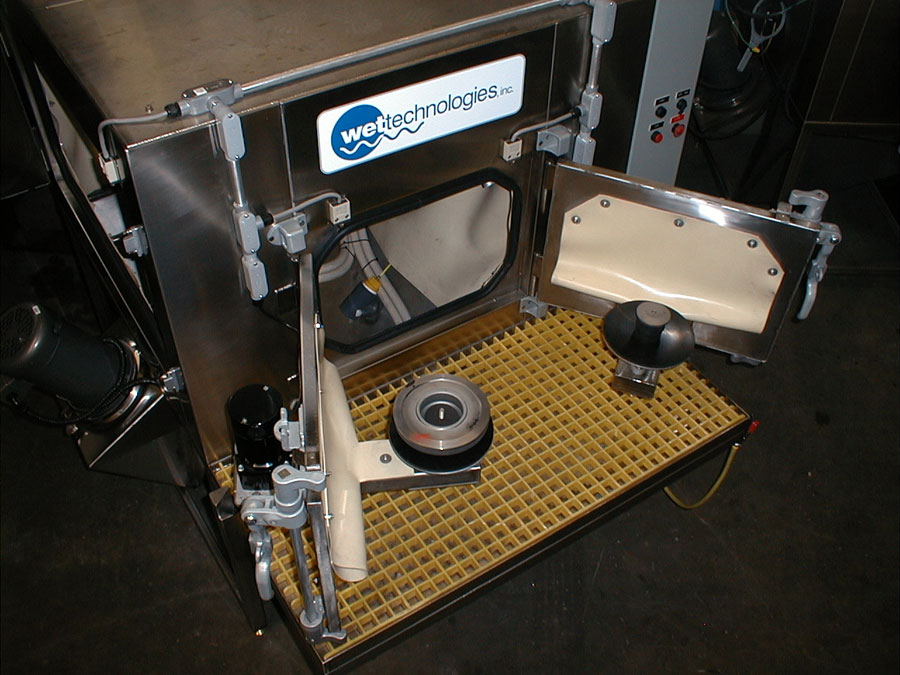

Back in 1999, in the basement of his home, Wet Technologies CEO and founder, Frederick Greis, began to conceive and develop the very first prototypes of what would quickly become his innovative wet-slurry, closed-loop, liquid abrasive systems. The early goal of those initial designs remains similar to today’s more advanced configurations: to provide industry with a smarter, faster, safer, cleaner and greener alternative to traditional chemical and dry blasting systems — easier to manage and more affordable to maintain.

The overall experience is outstanding, and our Wettech equipment

is going to make our job a lot easier.

Training and runoff went very well; looking forward to processing our

military marine pumps.

Smith & Wesson | The US Mint | Boeing | Sikorsky | Toyota | Curtiss-Wright | BorgWarner | Sturm, Ruger & Co. | Kimber America | Johns Manville | Coca Cola | to name a few…

Today, operating out of our state-of-the-art facility, Wet Technologies is proud to continue creating manual and automated wet blasting system implementations for many of the world’s most respected and celebrated manufacturing facilities, each unit proudly designed, developed and built in the USA. World-class brands use one or several of Wet Technologies groundbreaking liquid abrasive systems to achieve fast and effective metallurgical and composite surface processing for a variety of diverse industries and applications.

Wet blasting applications include extensive cleaning, degreasing, deburring and descaling, as well as removal of paint, chemicals and oxidation, right down to high-precision composite etching and finishing, surface profiling, polishing, texturing and more. No matter how heavy-duty or detailed the job, a liquid abrasive or pressurized water surface processing and cleaning system from Wet Technologies has the capability, flexibility and versatility to deliver. And since it’s all closed-loop and self-filtered, no waste pollutes the environment!

Quality Assurance

Our Quality Assurance Program dictates that all of our cabinets and systems are subjected to a rigorous check list during and after completion of construction. We continuously update our manuals and include training videos covering important maintenance and operating topics.

All visiting customers receive comprehensive training on their new Wet Technologies system. We engineer installation, operation, and maintenance to get the best performance from your equipment.

We offer installation and onsite start-up training, along with periodic system checkups. These can also be performed by our local factory trained distributors.