Minimize Hazards, Maximize Automation for Coin Minting

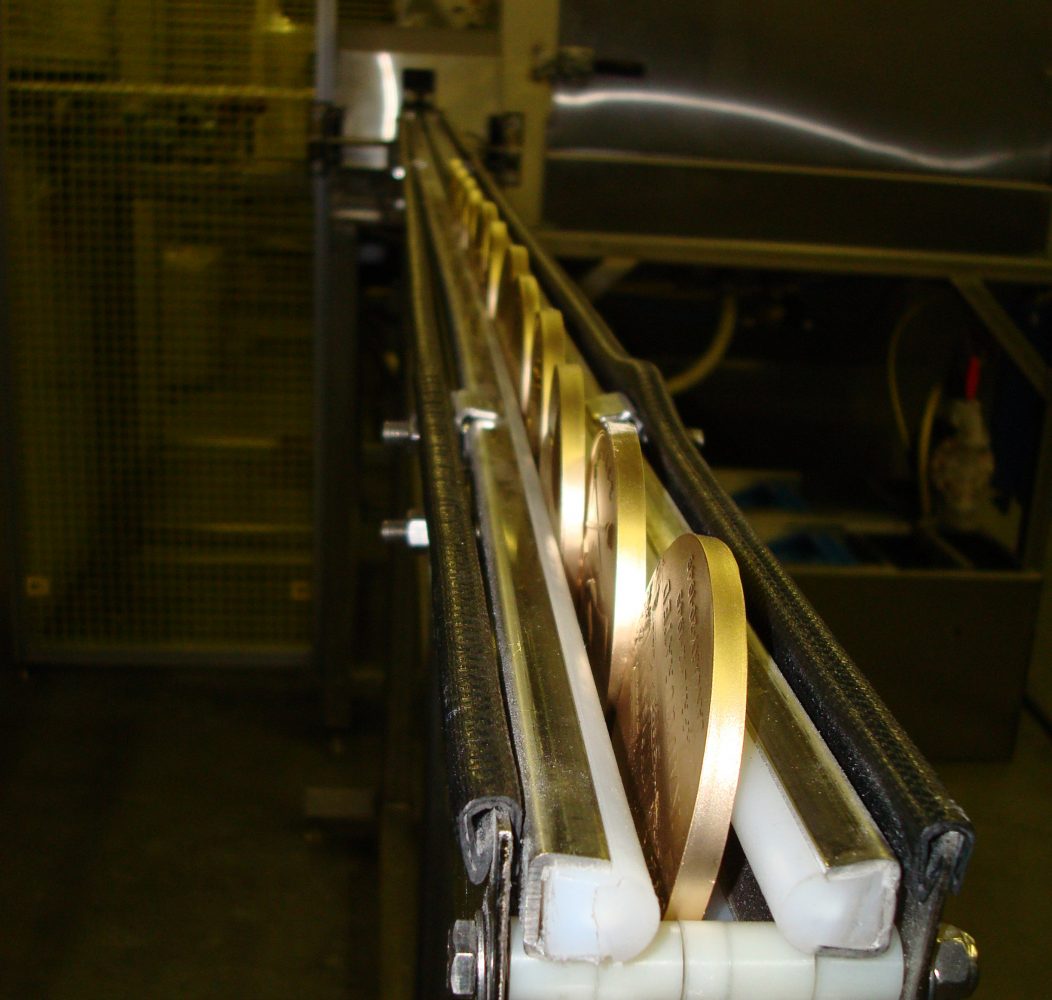

The Philadelphia branch was hoping for a solution that would minimize the use of caustic chemicals in their coin manufacturing process, chiefly because they didn’t believe this step could be eliminated altogether and still achieve the requisite finish on the coins. However, with a fully automated, self-filtered, closed-loop wet-slurry system by Wet Technologies, utilizing ceramic media under very specific pressures, not only was the use of caustic chemicals completely eliminated from the process, but the extra step of dry blasting was cut, as well, eliminating the dust that also compromised employee health and safety. With a fully automated, six-axis robot system that loads, descales, rotates, rinses and unloads the coins automatically, throughput for the mint’s coin finishing process leaped to one coin processed every 45 seconds, not only ensuring a safer work environment, but also a faster and more productive one.

Additional branches of the US Mint — those located in Denver, San Francisco and West Point — have now come to Wet Technologies for the design of similarly automated systems for application in various gold, silver and bronze commemorative coin and medallion minting. Today, the Wet Technologies automated system is now a featured stop on the plant’s public tour.

Additional Benefits for the Coin Minting Industry Include:

- Minimal reduction of substance maintains material’s value.

- Ability to etch, rinse and dry surfaces in a non-chemical, water-based, closed-loop system in one integrated, multiple-step work cell improves workflow.

- Dust-free, wet-slurry process allows for location of work cell in close proximity to sensitive production areas and keeps items on premise.

- Elimination of dust collectors and static electricity reduces related health hazards, safety issues and maintenance headaches.

Who In the Coin Minting Industry Relies on Solutions from Wet Technologies?

The US Mint in Philadelphia —

Design and development of a fully automated, six-axis robot system for loading, descaling, rotating, rinsing and unloading 3-inch silver commemorative coins, eliminating the need for hazardous caustic acid washes and dust-producing dry blasting.

Tiffany & Co. —

Utilizing a manual WetTech system, this company removes  investment material while minimizing steps to get closer to the final finish. As a bonus, they eliminated the dust collectors and the need to send them out to reclaim precious metals previously lost to dry blasting.

investment material while minimizing steps to get closer to the final finish. As a bonus, they eliminated the dust collectors and the need to send them out to reclaim precious metals previously lost to dry blasting.

Back to Coins & Precious Metals Intro