What is Wet Blasting?

“Wet Blasting” is an industrial process in which pressurized wet slurry is applied to a surface for various cleaning or finishing effects. Also known as “wet abrasive blasting” or “vapor blasting”.

How Does It Work?

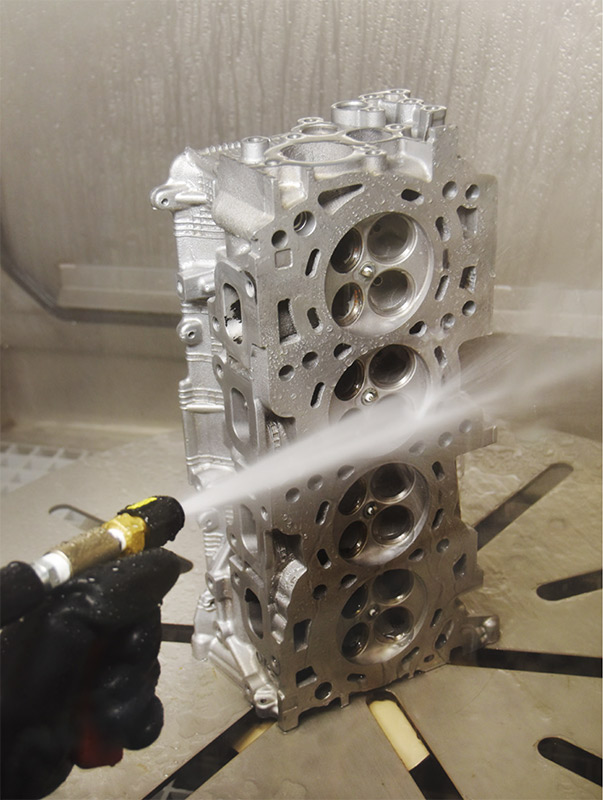

A specially designed, high volume pump mixes abrasive media with water. This slurry mixture is then sent to a nozzle (or nozzles) where regulated compressed air is used to adjust the pressure of the slurry as it blasts the surface. The liquid abrasive effect can be precision engineered to produce desired surface profiles and textures.

What is Wet Blasting Used For?

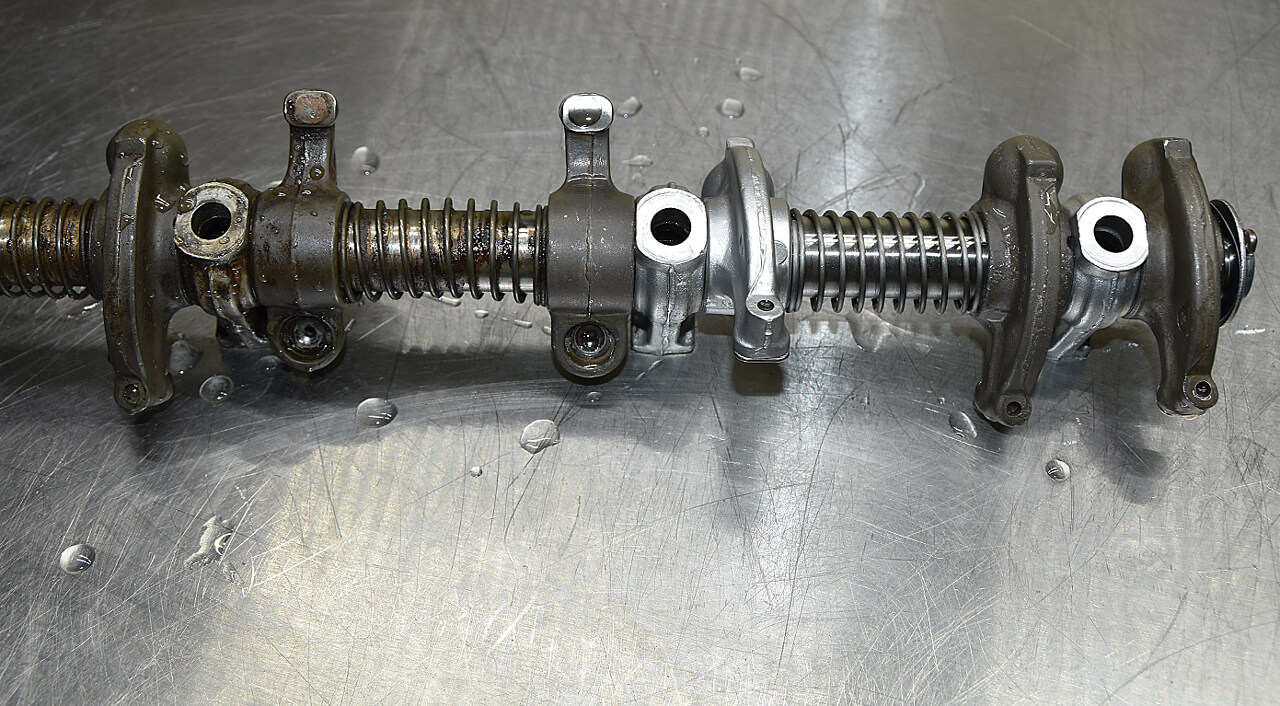

Industrial applications include extensive cleaning, degreasing, deburring and descaling, as well as removal of paint, chemicals and oxidation. Wet blasting is perfect for high-precision composite etching for bonding. The Wet Tech Process is a sustainable, repeatable method for precision parts finishing, surface profiling, polishing, and texturing of metals and other substrates.

What Types of Wet Blast Systems Are Available?

Manual Systems are typically cabinets with glove ports that allow the operator to position or turn the part or product being blasted.

Automated Systems allow parts or products to be moved through the system mechanically; on a conveyor belt, turntable, spindle, rotary indexer, or tumble barrel. They may be seamlessly integrated into a factory system, or loaded and unloaded manually.

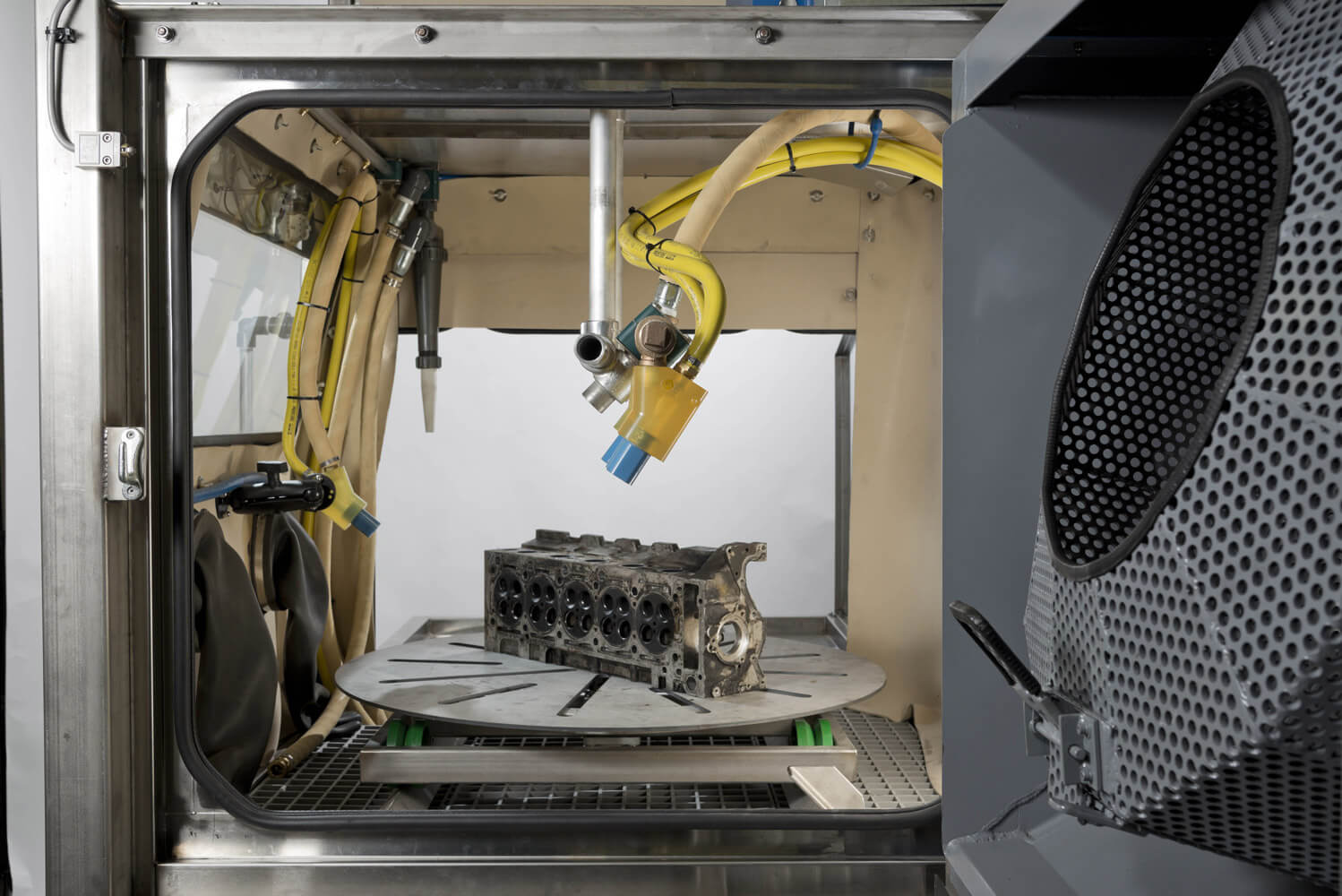

Robotic Systems are programmable surface finishing systems that allow the user to repeat complex processes with maximum precision and minimal labor.

Ask Us How Wet Blasting Can Improve Your Operations.

Call us at 856-303-8770 or fill out the form below to request information about integrating an advanced wet blast system into your manufacturing process.

© 2020 Wet Technologies, Inc. | All Rights Reserved