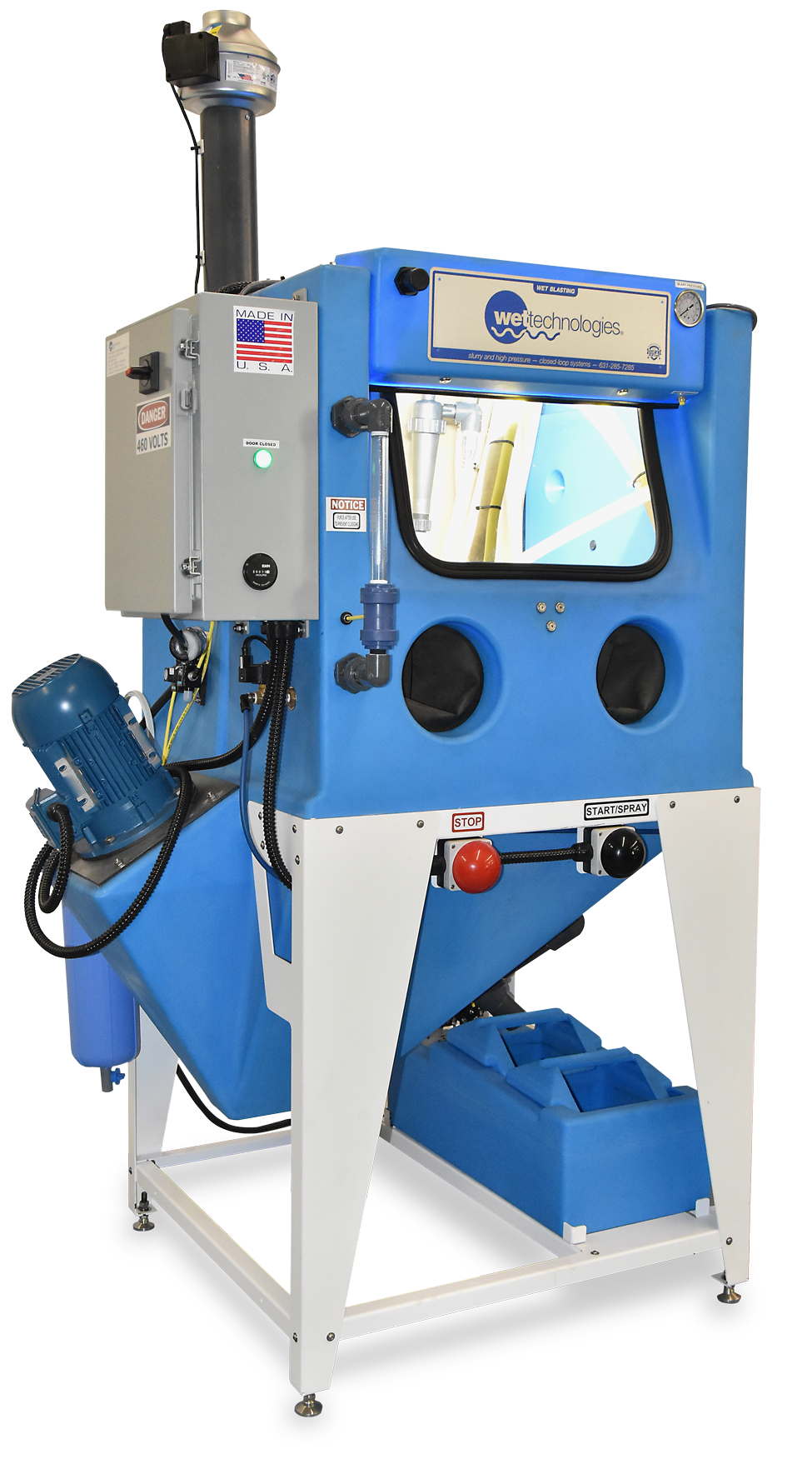

Making Industrial Grade Wet Blasting Affordable.

Manual Systems, Now in a 36” x 36” Design.

- Proprietary high concentration pumping system produces an even finish

- Closed loop filtered rinsing is standard

- Dust free blasting and rinsing

- Durable rotational molded corrosion-proof cabinet

- Available HEPA air management

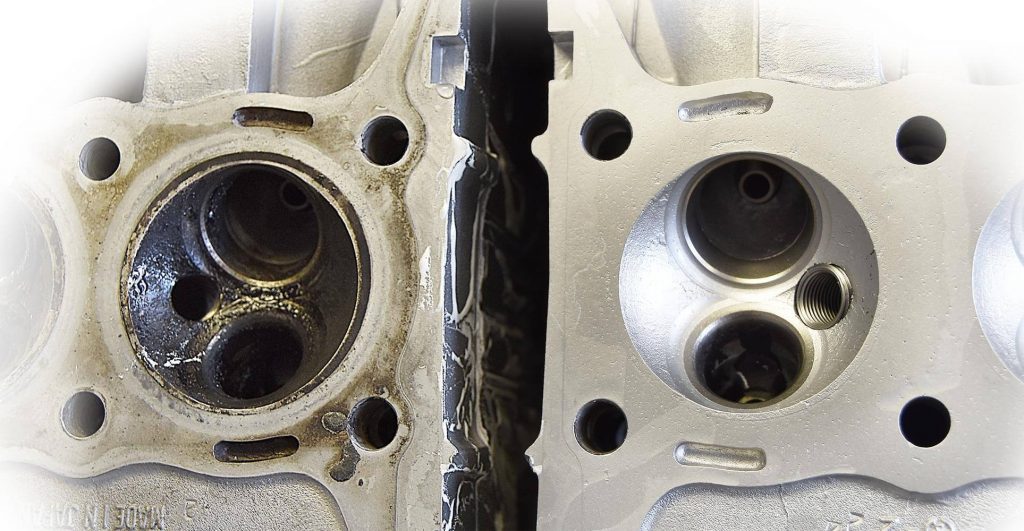

WT36-RP3 FORCE: Ideal For Light Remanufacturing

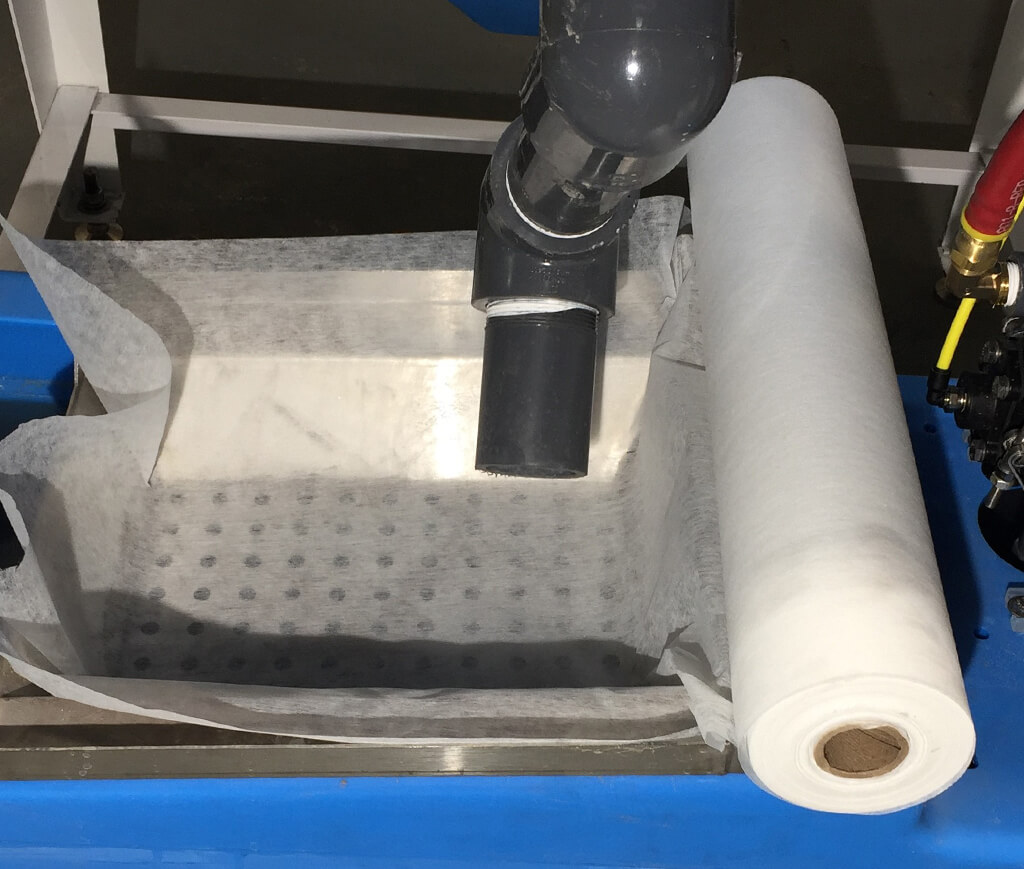

Closed loop filtration system separates broken down media and particles with each cycle, and returns that water on-demand to the manual rinse gun AND pressurized window rinse.

Use with fine to coarse angular and spherical media.

Through our network of distributors, you receive a high level of factory trained support, along with a wide range of surface processing options. Backed by the best warranty available.

Common Applications for Small to Medium Sized Parts:

- Deburr and radius edges

- Smoothing / reducing Ra values

- Etch prep for coatings and bonding

- Light remanufacturing and de-oiling

- Cosmetic finishing

- De-rusting and de-oxidizing

- Blending machining marks

Ask Us About Factory Options, Starting With:

- Push button media monitoring

- Heated slurry and rinse to aid in oil separation and cleaning

- Booster and HEPA to atmosphere exhaust systems

- Stainless portable turn tables—18” and 24” with covers

Look for New Configurations in the FORCE Product Line.

Wet Tech In-House Services:

Our laboratory provides testing and short run job shop processing.

Ready to Go! Economically Priced.

Call us at 631-285-7285 or fill out the form below to to schedule testing and request a proposal.