What You Need to Know About Wet Soda Blasting

From cookies to cleaning to health benefits, the versatility of baking soda makes it a powerful substance beyond the kitchen. In fact, after realizing sand was too abrasive, engineers even used it to safely [...]

How Data Acquisition Improves Manufacturing Processes

As the world’s technology continues to advance and evolve, the manufacturing industry has seen significant improvements. By partnering human expertise with machine learning and labor, manufacturers have made processes faster and less costly than [...]

7 Ways Robotics Can Improve the Wet Blasting Process

The world has seen a significant rise in automation in recent years, and industries across the board have been impacted. Although every industry has reacted differently to changing technology, manufacturing has embraced automation, making [...]

How to Improve the Peening Process

Heavy machinery and equipment is a significant investment for any company, so it’s crucial to ensure the metals used to craft them are durable and made to last. Peening is the process of purposefully [...]

How to Improve the Grinding Process

Grinding surfaces can be both complicated and time-consuming. Wet blasting will help you move through the finishing process more efficiently. Wet blasting is also more forgiving than grinding or sanding as it’s less likely [...]

How to Improve the Descaling Process with Wet Blasting

Descaling is vital to keep equipment running smoothly. Proper descaling removes the buildup of oxides, calcium, water, limescale, rust, and other non-soluble deposits. Typical descaling processes may involve sandblasting or caustic chemicals. Wet blasting [...]

What You Need to Know About Measuring Surface Finish and Wet Blasting

Surface finish can be described by three basic characteristics: lay, waviness, and roughness. Lay refers to the directional pattern on the surface, either inherent in the material or produced by the manufacturing process itself. [...]

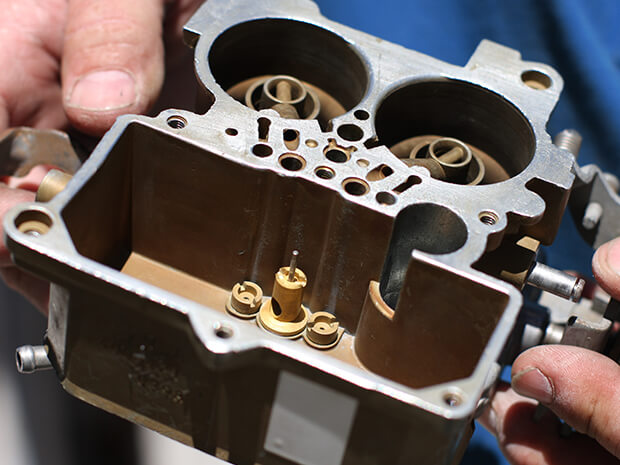

Attention Shop Mechanics: Clean Your Fair Share of Engine Parts? Consider a Wet Soda Blasting System.

What Is Wet Soda Blasting? Enclosed in a self-contained cabinet, wet soda blasters force a pressurized slurry of sodium bicarbonate through a tube and nozzle. By manually spraying the slurry against all surfaces of [...]

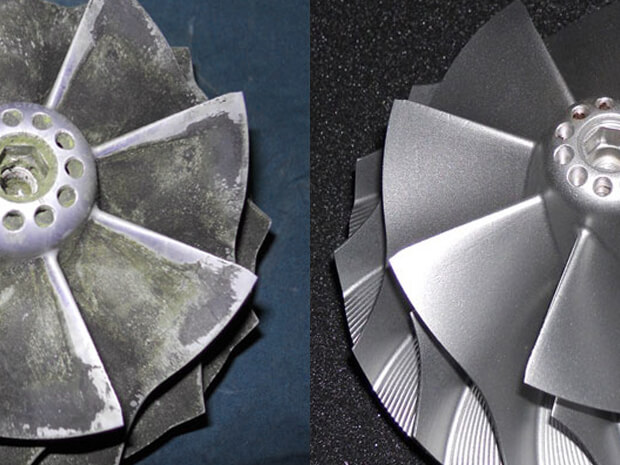

Industrial Grade Wet Blasting is Now Affordable for Small to Mid-Size Shops

Restore metal and plastic parts for motorcycles, cars, lawn maintenance equipment—even components for homes, buildings and utilities. A huge advantage over sandblasting, the water in wet blast slurry acts as a lubricant between the [...]

DPI and Wet Blasting

Dye Penetrant Inspection works well for a variety of product forms including castings, forgings and weldments. The structural steel, automotive, petrochemical, power generation and aerospace industries utilize liquid penetrant inspection. Wet Blasting has become [...]

Improving Your Deburring Processes

Common deburring processes include vibratory finishing, electropolishing, abrasive blasting, brush deburring, chamfer and radius cutters, and that old standby, hand deburring with files, abrasive pads, and scraper knives. The problem with many of these, [...]

RIT Researchers Use Collaborative Approach to Help Get a Handle on Pandemic

by Rich Kiley GIS, CIMS Lead Project to Clean Hundreds of Door Pulls on Campus to Help Inhibit Spread of Virus Soon after the coronavirus outbreak last spring, RIT researchers supporting the response to [...]

Remove the Burrs. Improve the Product.

Nearly every machining process leaves some sort of burr that must be removed. But few agree on the definition of a burr, let alone a standard for describing them. “A burr to one engineer [...]

Non-Destructive Paint Removal and Degreasing

You may already know that wet blasting is a clean, safe way to remove grease and paint for MRO, MX, and Reman applications. Toxic coatings are safely removed and contained [...]

Why “Made In America” Is Important To Us at Wet Technologies

Is it really beneficial to shop globally, and buy from the lowest bidder? While we may save a few dollars on the initial purchase, the total cost is often higher in the long run. [...]

Quality Control Gets Right In Line with Surface Finishing.

Collecting data from sensors to monitor machine performance and product quality is not a new concept. We’re quite familiar with the “stop/start” function that signals when a part is out of place, [...]

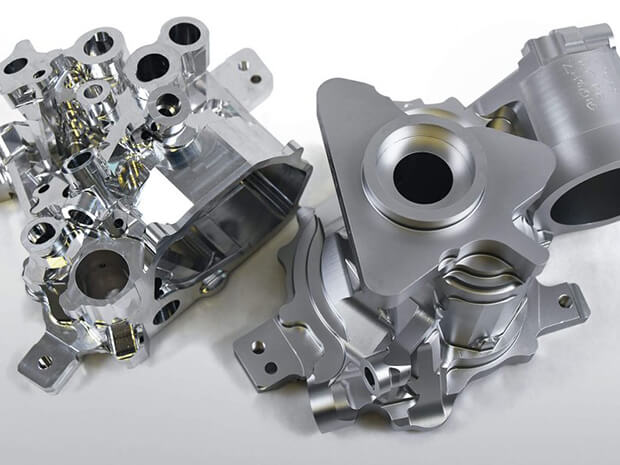

Custom Engineered Wet Blast Systems for Emerging Applications

The Fourth Industrial Revolution, whether you call it Industry 4.0, or Manufacturing 4.0, is opening doors to higher productivity, smarter workflows, and safer work environments. As we integrate advanced robotics, artificial intelligence (AI), IoT, [...]

7 Reasons to Choose Wet Blasting Over Chemical Dip

Eliminate caustic chemicals and their expensive disposal cycle. Reduce process steps, saving time, labor, and space on your factory floor. Prep parts for bonding, painting, plating or coating. Often, wet blasting alone [...]

6 Reasons to Choose Wet Blasting Over Dry Blasting

If you’re still using dry blast equipment and PPE (Personal Protective Equipment), now is the time to re-think your surface prep and finishing processes and choose wet blasting over dry blasting. 1-Enhance worker safety. [...]

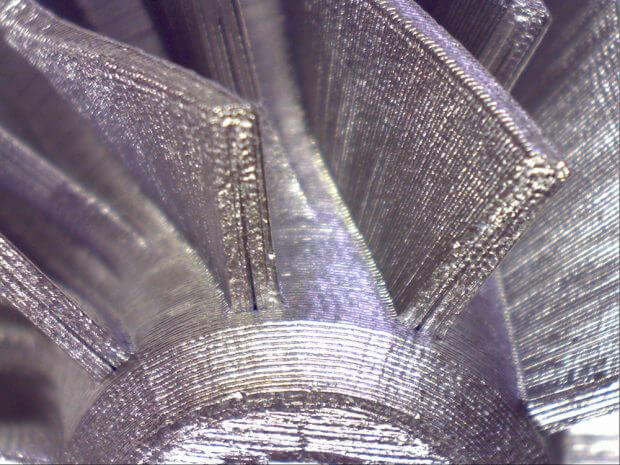

Wet Blasting and Additive Manufacturing: Two Young Technologies “Made” for Each Other.

Wet Blast cabinets designed by Wet Technologies are a perfect match for Additive Manufacturing, particularly for parts being made on demand—even in the field. Applications include surface smoothing, preparation for inspection and protective coatings. [...]

Aluminum Finishing Levels the Field for Consumer Tools Being Made in the USA.

The market for consumer goods is so competitive, manufacturing in the US often seems cost-prohibitive. But Wet Technologies worked with Empire to freshen up the look of its levels for consumer appeal, while eliminating [...]