Common deburring processes include vibratory finishing, electropolishing, abrasive blasting, brush deburring, chamfer and radius cutters, and that old standby, hand deburring with files, abrasive pads, and scraper knives. The problem with many of these, as Gillespie has said, is that they can affect more than the burr.¹

“When determining which one is most effective, shops must assess a variety of factors, including the burr height and thickness, workpiece material, allowable edge radius, maximum stock loss in the surrounding area, required surface finish, and, of course, the number of parts that will be produced and therefore the economics,” he said. “For many of today’s commercial products, any negative effects of the deburring process are small enough that they can be ignored, but for precision parts, it is essential to evaluate these impacts early on in the manufacturing planning stage.”¹

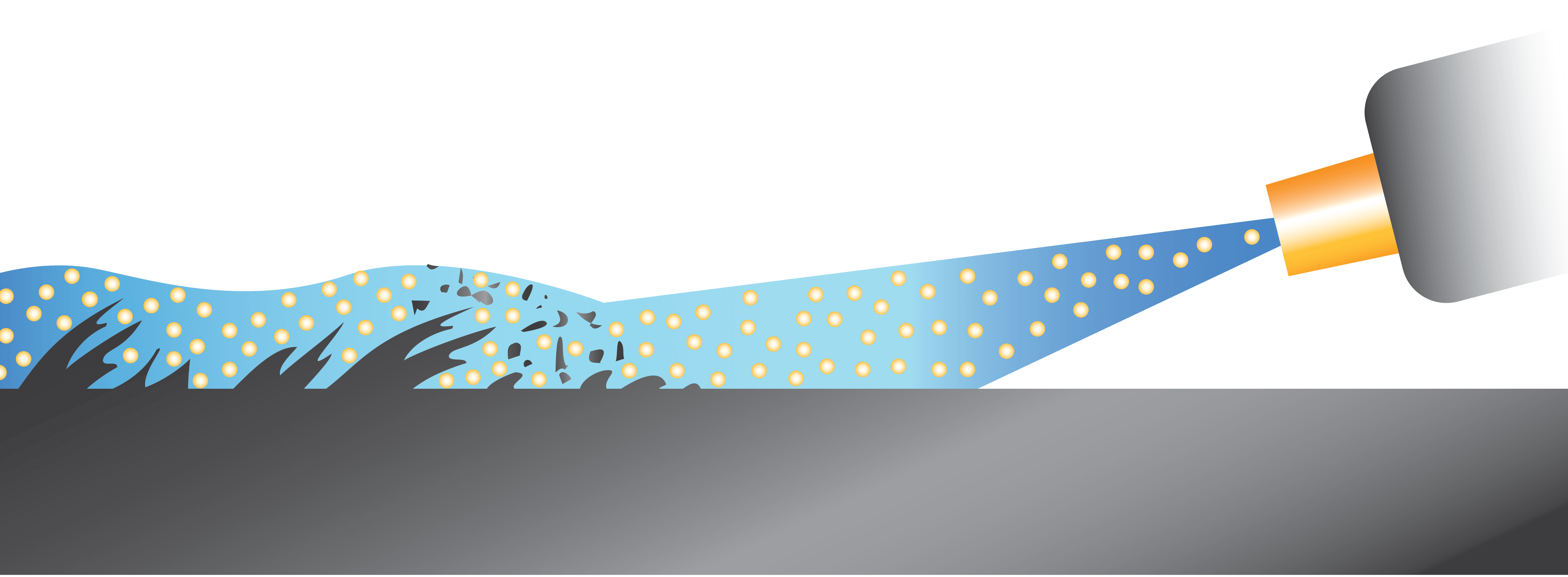

Wet blasting offers several surface finishing advantages, especially for those situations in which the negative effects of deburring may be unacceptable. Wet blasting allows you to “come in shallow,” meaning that the angle of contact can be less aggressive than other methods. It creates a kind of scrubbing action, or erosion of the burrs, allowing a more precise and less destructive handling of precision parts.

Wet Blasting the surface at a shallow angle erodes the burrs, leaving a smooth, uniform surface.

Deburring for Precision Machining

Wet blasting removes fine burrs in machined parts. Automating the process reduces labor while increasing volume and speed. Water in the slurry helps dissipate heat. High-level materials like titanium can be efficiently deburred in a Wet Tech system with no dimensional damage, while leaving a clean, uniform, matte finish.

Deburring for Aerospace

When deburring parts with intersecting or cross-drilled holes, such as hydraulic manifolds and valve bodies, it can be difficult to reach the target area with traditional deburring tools.¹ The Wet Tech Process is ideal for reaching these kinds of internal passages. It’s precise, repeatable, and unlike other methods, it removes the burrs without altering the dimensional characteristics of the part, or leaving abrasive media embedded in the surface of the part.

Deburring for Automotive

Stamping of transmission splines leaves fine burrs that can be removed with a Wet Tech system in seconds, with no media imbedded in the surface. At the same time, wet blasting prepares the inside for a pressed bearing. Deep, sharp stress risers left by broaching are removed with fine slurry blasting. The result is a very large increase in lifecycle [from the effects of fatigue].

Deburring for Firearm Manufacturing

Unlike dry blasting or sand blasting, wet slurry blasting can easily reach otherwise inaccessible surfaces of the slide to leave the part fully deburred. Using the same Wet Tech system, but set under lighter pressures, the slide can then undergo a secondary lapping process that leaves an ultra-smooth and cosmetically superior finish.

Deburring for Medical Implants and Devices

Medical implants require special profiles that support bone re-growth, plating adhesion, or a low Ra blended finish. Dust, embedded dry abrasive, and limited floor space in the manufacturing environment are traditional challenges. The Wet Tech Process has enabled radical changes in workflow and design. The ability to have dust-free work cells next to manufacturing stations increases productivity and preserves surface integrity. Precise manufacturing control, low maintenance needs and the easy operational requirements speed ROI and reduce TCO.

Test Your Parts in Our Lab to Find the Best Deburring Process for Your Factory.

- Save time by combining deburring, lapping and polishing processes in one cabinet.

- Minimize or eliminate the use of chemicals and their disposal.

- Eliminate airborne dust and imbedded abrasive.

Batch Loaded, Rotary Indexing, and Robotic Systems are available. Contact Wet Technologies to discover how wet blasting can resolve your deburring challenges.

¹https://www.sme.org/technologies/articles/2019/december/sizing-up-deburring-operations/