Descaling is vital to keep equipment running smoothly. Proper descaling removes the buildup of oxides, calcium, water, limescale, rust, and other non-soluble deposits. Typical descaling processes may involve sandblasting or caustic chemicals. Wet blasting is an alternative and effective solution to the problem with less risk and no mess.

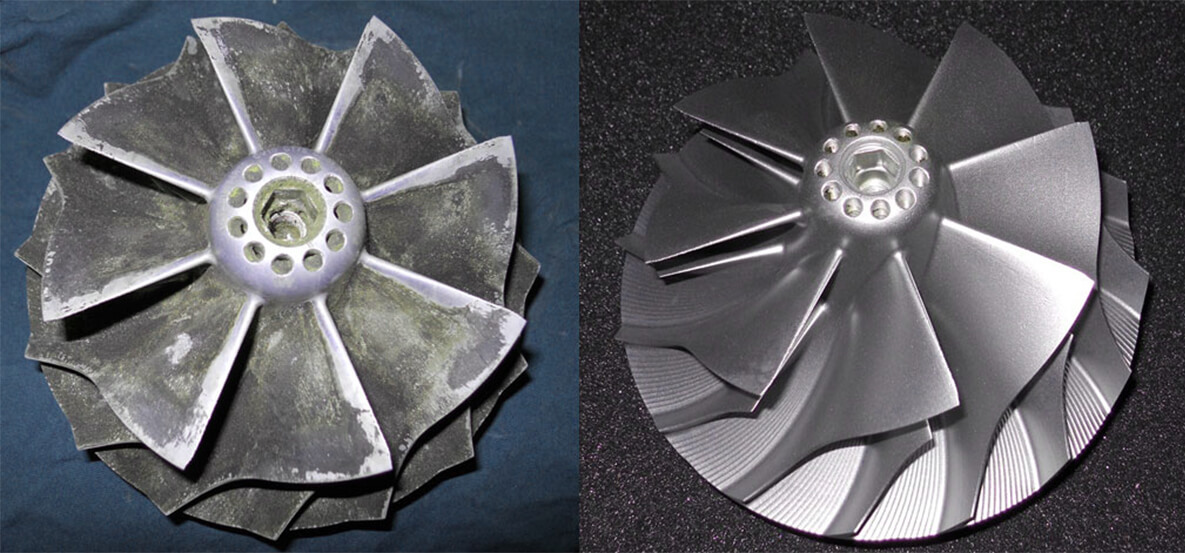

Wet blasting further improves the descaling process as it removes the scale without causing any damage to the substrate material. This method results in a smoother, more consistent finish in comparison to other methods.

Descaling for Aerospace

Wet blasting is a dependable method to ensure thorough cleaning in the aerospace MRO industry, providing a precise clean finish even in small crevices, and consistently throughout the material. For example, in surface preparation, wet blasting can remove heat scale from the turbine blades, deep clean, and remove contaminants when servicing a jet engine.

In aerospace, it’s essential to reduce downtime, and with wet blasting, you can achieve a sleek finish, ridding your equipment of scale buildup quickly and efficiently.

Descaling for Industrial Processes

Industrial wet blasting improves the process by removing scale buildup and other contaminants from metal parts with a high-pressure spray of water mixed with abrasive material. The slurry breaks down scale and grime and removes loose particles. Using wet blasting for descaling doesn’t just provide an efficient finish, but also helps to improve quality control by reducing scrap rates.

Descaling for Automotive

When you are doing bodywork on a vehicle, rebuilding the engine, replacing parts, or painting, your end goal is a smooth finish. It’s essential to descale before you begin the work. Wet blasting removes scale buildup even in the tightest areas. One significant benefit of wet blasting over dry blasting to remove scale is eliminating dust in your shop. Not to mention, wet blasting won’t involve any harsh chemicals or hazardous disposal through the reman process.

Whether you’re servicing a jet engine or rebuilding a carburetor, Wet Technologies can help you with your descaling process. To get the most effective and cleanest finish, contact us today. Let’s save you time and effort, as we increase productivity.